Cylindrical Shells

#1561

Posted 05 July 2010 - 07:19 PM

#1562

Posted 08 July 2010 - 09:05 PM

What size is the actual shell Karl ?Here are some pictures

0084 : Strip of card enough for 2 turns around 3/8" former 1" wide also paper for 2 turns and overhang.

0085 : Pasted card rolled around former.

0086 : Rolling card in paper leaving enough both ends.

0087 : Rolled.

0088 : End sealed.

0090/0093 : Showing beraq inside shell.

Obviously these are not filled, when they are the end will be closed and then rolled in two more turns paper and sealed well at both ends. When fully dry the beraq are dipped in 50:50 pva/water and dried once more. Then the hole of 1.4mm brass pin is made, the delay is then inserted using a small knife. The timing depends on paste and how hard I push the delay in. Then the beraq are primed with fine grain BP.

If enough intrest I can bring some unfilled beraq and parts to Stanford Hall maybe give 'quick' demo on making them as I will be needed live side rigging.

Also added picture of a 3/4" ID second noise Beraq. It was used to practice filling delays.

#1563

Posted 11 July 2010 - 01:58 PM

What size is the actual shell Karl ?

I believe its 2.8 inch Id.

#1564

Posted 11 July 2010 - 06:12 PM

Total Beraq,

18 No - 5/8" ID Orange

18 No - 5/8" ID Aqua

#1565

Posted 11 July 2010 - 07:32 PM

#1566

Posted 11 July 2010 - 07:40 PM

When you say 50:50 PVA:water are you talking a 50% solution of solid PVA in water, or a 50:50 mix of white glue and water?

Mumbles, this is meant as White glue / water 50:50 mixed. This is just used to dip the beraq and fill any holes. Also stops the spiking unwinding.

#1567

Posted 12 July 2010 - 12:45 AM

The lift charge is something you have to fine tune your self. It depends on the BP quality, BP mesh, "mortar-shell gap" and the shell's wheight. And how high the builder likes it to travel.

Good guide lines for spherical shells are 30 grams for a 3" and 40 grams for a 4" +- 5 grams. Cylindrical shells tends to be higher and this adds on some extra wheight. (I use about 15 grams of lift for a 2" cylindrical shell of ~70 grams.)

The mesh size is not critical. For 2-3" shells a grain size of 2-5mm is something to start with.

One second time fuse is something to start with for a 2-3" shell.

I know a lot of people has a lot to say about lift and time fuses. I can only say one thing:

-You have to find out the correct parameters your self.

Pyro is not an exact science.

EDIT: By the way your shell looks nice :-)

#1568

Posted 12 July 2010 - 12:48 AM

NICE TO KNOW YOU.

IF YOU HAVE ANY OTHER QUESTION, FEEL FREE TO ASK.

I AM THE PROFESSIONAL FIREWORKS MANUFACTURE. AND I THINK IF YOU HAVE THIS KIND OF QUESTION, CONTACT ANY TIME IS OK.

#1569

Posted 12 July 2010 - 06:18 PM

#1570

Posted 04 September 2014 - 06:51 PM

Hi,

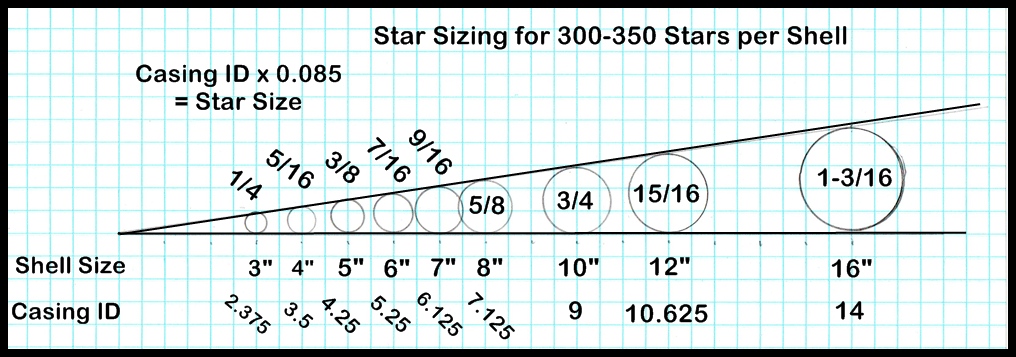

What is the ideal size for colored star in 1,2-inch (30 mm) cylinder shells?

The burst look sparse and the stars will burn too long, when using 1/4-inch colored stars pressed with Wolter Pyro's star board. Only 25 to 30 pieces of 1/4" stars go in a 1,2-inch shell !

I hand press my COLORED STARS using a STAR BOARD. I use barium chlorate and potassium chlorate for my stars, because potassium perchlorate stars burn to slowly.

QUESTION: So, what will be the ideal size? 3⁄16" (4.8 mm) or even smaller 9⁄64 (3.6 mm) ?

Thanks,

Philipp

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users